IES Inspection Services in Bangladesh

Overview of IES Inspection Bangladesh.

In September 2016, UK based IES Inspection Limited ventured into Asia by opening a new sister company in Bangladesh.

The new company will focus, though not exclusively, on textile quality control inspection services. Textile quality control inspection involves the monitoring and control of garment and clothing items that are produced in Bangladesh from textiles such as cotton and synthetic materials.

Softline

Textiles (fabrics, home furnishings)

Garments

Shoes

Bags & accessories

Hardline

Furniture

Home and garden equipment

Kitchenware

Bathware

Tools & Hardware

Toys & juvenile products

Sports gear

Sundries

Electrical and Electronic Products

Household electrical items

Lighting fixtures

Frozen Foods Products

Frozen Shrimp and Prawn

Frozen Fish

Fresh and Chilled Fish

Inspection Services

Initial Production Inspection (IPI)

Our initial production Inspection (IPI) is an examination of components, materials and product quality at the start of production to foresee risks and prevent resources being wasted.

A factory usually cannot turn defective inputs (components, or raw materials) into good products. And the problems are much harder to detect once the materials are embedded in the final product.

Thus, to decrease quality risks, the inputs can be inspected prior to production. Some samples can be taken randomly and checked visually (or sent to a laboratory for tests). Also, the buyer should clearly define what inputs are acceptable, before he gives any order.

Our experienced inspector can also examine the making of a prototype/sample, to make sure of two things:

Has the factory understood the technical files? Do they know what product the client wants?

Has the development team clearly communicated the requirements to the manufacturing team? Is the equipment for mass production similar to that used for making prototypes?

Conducted when 10% of goods have been produced, our initial product inspection is applicable to all goods, checking them with regulations, standards and contractual agreements. It is a visual evaluation that detects early defects and is performed on-site.

At each stage of the production cycle our IES inspector will produce a full and detailed inspection report, together with a photographic record within 24 hours of the inspection allowing you to see the work undertaken. We have a global network of inspectors and can arrange your inspection within five working days of receiving your request.

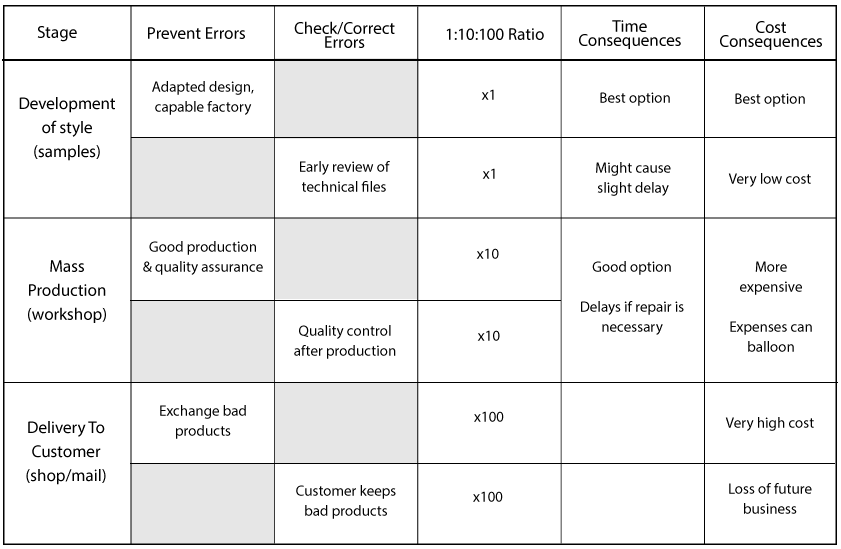

There are only six ways to deal with defects. They can be either prevented or corrected, and they fall into three broad categories: development, production, and delivery.

For all inspections, IES Inspection uses the standard internationally recognized BS (ISO 2859-1) statistical sampling procedure. These comprehensive criteria cover: functionality, performance, durability, overall appearance, and dimension.

Benefits of Initial Inspection:

- Detect mistake and misunderstanding from your factory earlier.

- Make sure your goods are conformed to your specifications and expectations

- Avoid delay and extra cost

- Check the quality of your product and the reliability of your supplier

- To save money by outsourcing the quality control of your product by an expert inspector directly on the field and before it is too late

- Check if the factory is respectful to your previous recommendation

During Production Inspection

The During Production Inspection (DUPRO or DPI), or In-line Product Inspection (IPI), checks semi-finished or finished goods part-way through the production process. Generally, this takes place when between 40% of your order has been produced and 20% export-packed.

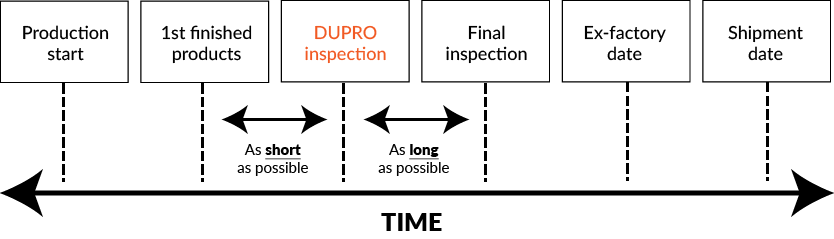

The ideal timing actually depends on the product type and the experience of the factory. But a few rules of thumb can be followed for 80% of consumer goods, if these conditions are true:

- The factory is used to making this kind of product involving this level of complexity,

- The cycle time to get the first finished products out of the lines is no more than 10 days.

In such cases, the below sketch is applicable:

Let’s take the example of an order of 20,000 pieces that takes 30 days to manufacture. If some finished products appear 8 days after production started, and if 600 products are available for inspection 4 days later (in the early morning), the good time for a DUPRO is 12 days after production start.

Benefits of During Production Inspection

- Reduction of Final Random Inspection failure risk

- Identification of possible delays

- Possibility to take corrective actions before production is finished

- No need for the client to be on-the-spot

Tailor-made to your requirements

Final Random Inspection

Final Random Inspection (FRI) is an on-site Product Inspection that monitors the conformity of production to your specifications.

Final Random Inspections (FRI) are by far the most popular tool for securing supply chain quality control for consumer goods. FRI normally takes place once 80% of the goods are available. The final result of an inspection usually triggers the shipment and the payment. The accuracy and reliability of your inspection report are crucial in order to take appropriate decisions regarding your products.

Based on the Acceptable Quality Level (AQL) tables, a random sampling of the goods subject to inspection is determined in order to statistically infer the quality of the lot. In most of cases FRIs evaluate three main aspects of product quality:

Conducted when 100 per cent of your goods are produced and at least 80 per cent are packed and ready for dispatch, final random inspections are a range of visual tests that cover:

Quality (appearance, performance, and workmanship)

- Quantity

- Packaging

- Labeling

- Shipping marks to achieve regulatory compliance (for example bar code checks)

- Transportation

- Drop checks

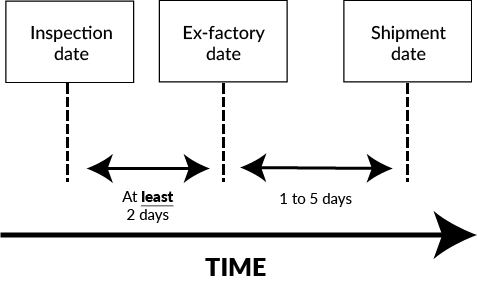

If these conditions are respected, the factory cannot hide defective goods in a back room. So timing is of prime importance when it comes to final checking. I drew a little sketch to represent the key dates to watch closely:

A final random inspection usually takes place in the factory, rather than in the forwarder’s warehouse (or nothing can be repaired). So it is performed before the goods are sent out of the factory.

Advantages

- Verify your goods before they are shipped

- Approve final payment in confidence

- Refuse the order if it does not meet your requirements

Container Loading Supervision

The Container Loading Supervision (CLS) will take place right before the vendor is supposed to load the products for shipment; it is aimed to supervise the loading process. This Container Loading Supervision in Bangladesh or anywhere in IES takes place at the factory. It can also be performed at your forwarder’s premises.

Container Loading Supervision (LS) checks that your order is both complete and securely loaded into its container before shipment. This inspection ensures that the goods delivered by the factory are compliant with your requirements in terms of quantity, assortment, and packaging.

A container loading inspection also ensures that the export cartons are securely loaded into the container, and that the container is in good condition (clean, dry, damage and odor free).

We check

Quantity check, packing list check, the container conditions, the loading process (cartons conditions, filling-up level etc), a quick look at the packaging & packing of your products.

If you need extensive Quality Control checks on product specifications based on AQL standards, you could also request to perform a standard inspection, such as a Pre-shipment inspection or During production inspection.

All of IES’s inspectors are fully trained not only to supervise but to closely monitor the loading process. Before shipping they check the:

- Quality and condition of your goods.

- Quality and condition of packaging

- Adherence to correct goods handling procedures

- Condition of the container your goods are being transported in, including safety and cleanliness

- Correct loading of your goods and also verify all documentation

Benefit of Final Random Inspection

As your products will travel for days or weeks to reach the final destination, a Container Loading Supervision in Bangladesh and IES will secure your goods are loaded and packed efficiently and that products are not damaged during the shipment.

Highlights

We provide the status of the container itself.

- The right goods, no replacement of products possible.

- The quantity of boxes is exact.

- The loading will be done with care (limitation of broken goods due to loading).

- The inspector will call the office so that you get immediate feedback.

If you read your e-mails quickly and if you have instructed your vendor to wait for your green light before shipping, you have a chance of stopping disasters.

- The container is forwarded to your company.

- We note whether a seal is affixed on the container.

- We perform a final check on packing.

Auditing Services

Factory Audit

A factory audit is a tailor-made programme aimed at assessing a facility’s quality systems, workplace environment and capabilities in accordance with standards set by the client or IES. It ensures that your vendors and suppliers are able to undertake a specific order as per your requirements.

We often use the analogy that picking a Contract Manufacturer (CM) is like picking a spouse; you are going to be together for better or for worse and divorce could be very expensive. Whether you have a factory already chosen or you are about to choose a factory, you should perform a Factory Audit to understand the facility’s strengths and weaknesses relative to your own needs.

When you have these questions at the very early stage, it means you want to be certain that the factory can fulfill the order within the deadline and meet your required quality level. Factory audit can help you now.

With high qualified engineers and professional experience of assessing 120+ Bangladesh factories; we can help you make your crucial decision on whether you should trust and move forward with a potential Bangladesh supplier. A factory audit report with full information will be emailed to you within 24 hours and made available on the internet, from any computer, for exclusive use.

Our experienced auditors will personally go to the factory to represent your company’s interests by factory audit items below:

- Surveying the factory profile (such as organization structure, certifications, personnel, equipments, and facilities etc…)

- Assessing R&D facilities and capability

- Assessing production processes and its capacity

- Checking the quality assurance and process control system

- Checking previous production records and capabilities

- Taking pictures of every aspect so you can get the “feeling” of the factory

Benefits of a Factory Audit

- Through our factory audit, get the “feeling” of the factory without being on-the-spot. (Save you time, save you money).

- Make your crucial decision on whether you should trust and move forward with a potential Bangladesh supplier.

Social Audit

A social audit is a way of measuring, understanding, reporting and ultimately improving an organization’s social and ethical performance. A social audit helps to narrow gaps between vision/goal and reality, between efficiency and effectiveness.

“Pricing, products and services are no longer the sole arbiters of commercial success… it is business that must take the lead in taming the global frontier. Business must take the lead in establishing rule of law in emerging markets. Business must take the lead in stopping bribery. Business must take the lead in bringing order to cyberspace. Business must take the lead in ensuring that technology does not split the world into the haves and have-nots.”

To make sure that neither you nor your customers have regrets, We suggests you use our social accountability audit (COC audit) service. Our experienced auditors will go to the factory to represent your interest to check if it complies with international standard such as SA8000 which is developed by Social Accountability International. Thus we can help you find out what type of company you are about to do business with A report with full information will be emailed to you within 24 hours and made available on the internet, from any computer, for exclusive use.

We will personally go to the factory to represent your company’s interests by surveying:

- Child labor

- Forced labor

- Minimum wage

- Workplace safety and health

- Social benefits

- The right to organize

- Discrimination

- Working hours

- Protection of the environment

Benefits of a Social Audit

- Enhance your company’s image.

- Ensure that the supplier you have chosen is socially accountable.

- No need for you to be on-the-spot. Saves time and money.

Quotation for Goods Inspection

Tell us about your inspection requirements and we will arrange for highly trained and experienced inspector to visit your business, at a time that suits you, to ensure their is no disruption to your working day.

Complete the enquiry form for a quotation or contact us directly by telephone or email.

Contact IES Bangladesh

UK Register Head Office

Inspection & Engineering Services Limited

Unit 3, Lion Works,

Station Road, Whittlesford,

Cambridge, UK,

CB22 4WL

Contact Details

Phone: +44 (0) 7951 593 704

Email: info@iesinspection.com

Accounts Department: accounts@iesinspection.com

David Burke Director

Phone: +44 (0) 7951 593704

Email: david.burke@iesinspection.com

Bangladesh Country Office

Inspection and Engineering Services (Bangladesh) Limited

House ~275/A, Road #20,

Mohakhali DOHS, Dhaka – 1206, Bangladesh

Contact Details

Phone: +880 1706 314 222,

+880 488 10309,

+880 488 10310

Email: info@iesinspection.com

Accounts Department: accounts@iesinspection.com

Ahashan Habib Director & CEO

Phone: +880 2 9341259

Cell Phone: +880 1706314222

Email: habib@iesinspection.com